| Product Model | AIS/V42 | AIS/V60 |

| Range of containers | Plastic Bottles (PP/ PE), Glass Bottles | |

| Container specifications (ml) | 50-1,000 | |

| Max throughput of containers /min | 150-200 | 150-400 |

| Inspection Accuracy(μm) | ≥50 | |

| Inspection Range |

Foreign particles: plastic particles, glass particles, metal particles, coloured particles,

hair,

translucent fibres, and etc. Cosmetic Defects:closure defects, missing or damaged crimp stopper;cracks and deformations of container surface;base pull-ring defects. Overfill/ Underfill. |

|

| Features |

1. Effective targeted detection of most common particle contamination from container

materials:

plastic particles of PP/ PE bottles and glass fibres within glass bottles; 2. Effective detection of particles adhering to the inside of container wall; 3. Deep Neural Network based algorithm: unaffected by bubbles and liquid surface reflections, very low false alarm rate. |

|

| Power(kw) | 23.5 | 32 |

| Power supply | Three-phase AC, 380V/50Hz | |

| Air supply pressure (MPa) | 0.45-0.7 | |

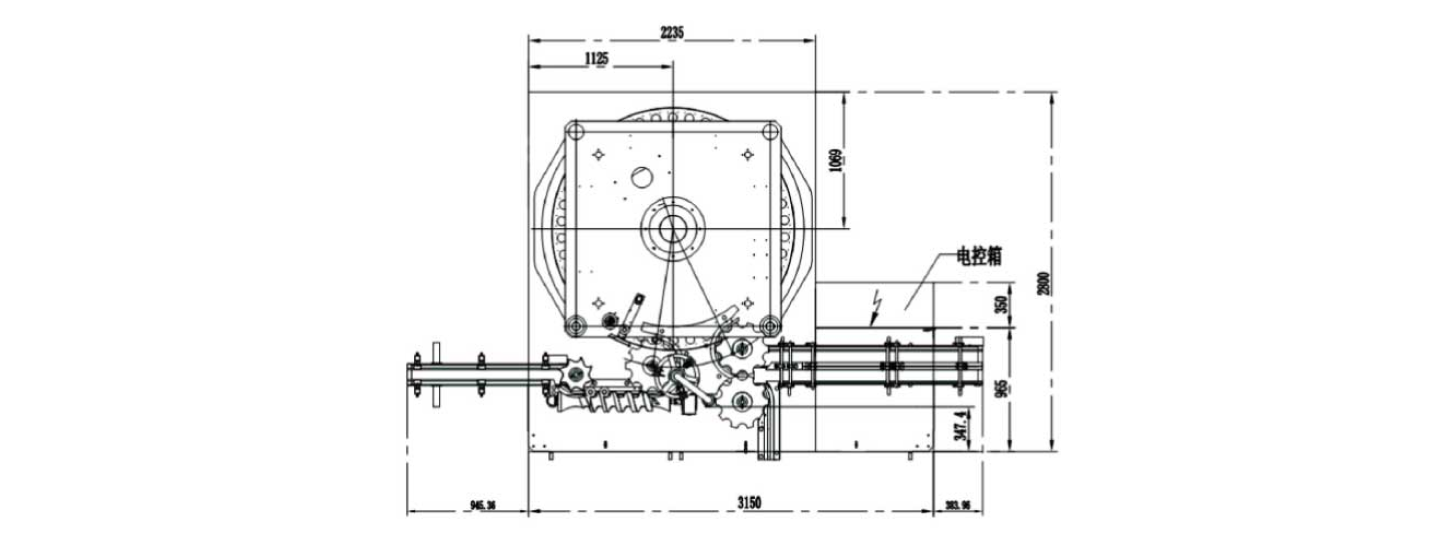

| Machine dimensions(mm) | 3,250 x 2,800 x 2,500 | 3,500 x 3,200 x 2,500 |

| Gross weight(kg) | 8,500 | 11,500 |

| Station Number | Inspection Station | Inspection Target |

| U1 | Cap Stopper Station | closure defects, missing or damaged crimp stopper |

| U2 | Bottom Station | Heavy particles on the bottom such as metal and glass; Cosmetic defects of the bottom and heel of container, including pull-ring |

| U3 | In-liquid Particle Station | Coloured particles, black/ white particles, hair, glass particles, insects, other non-transparent impurities |

| U4 | Floating Particle Station | Floating particles: especially plastic particles and fibres on liquid surface, also insects, hair |

| U5 | Transparent Fibre Station | Transparent fibres such as plastic fibres, hairs |

| U6 | Particles on Container Wall Station | Particles and contaminations adhering to the container wall: covering both below and above fill level |

| U7 | Cosmetic Station | Cosmetic defects on the side of container: cracks, scratches, material deformations, irregularities within glass, dirt |

| U8 | Fill Level Station | Over/ Underfill beyond tolerence threshold |